IDEA Factory

College Park, Maryland

Contract Value: $10,098,966

GC: Clark Construction

Owner: University of Maryland

Engineer: EYP

Project Description

University of Maryland’s Clark School of Engineering is expanding with a 60,000-sf. world class research facility on the corner of Paint Branch Dr. and Stadium Dr. at the College Park campus.

The goal of the E.A Fernandez Idea Factory is aimed towards promoting collaboration, innovation and entrepreneurship. The new Maryland facility contains a new rotorcraft laboratory, robotics realization laboratory, advanced/additive manufacturing laboratory and a quantum technology laboratory – requiring over 3,100 linear feet of specialty lab gas piping to NFPA99 standards to be implemented.

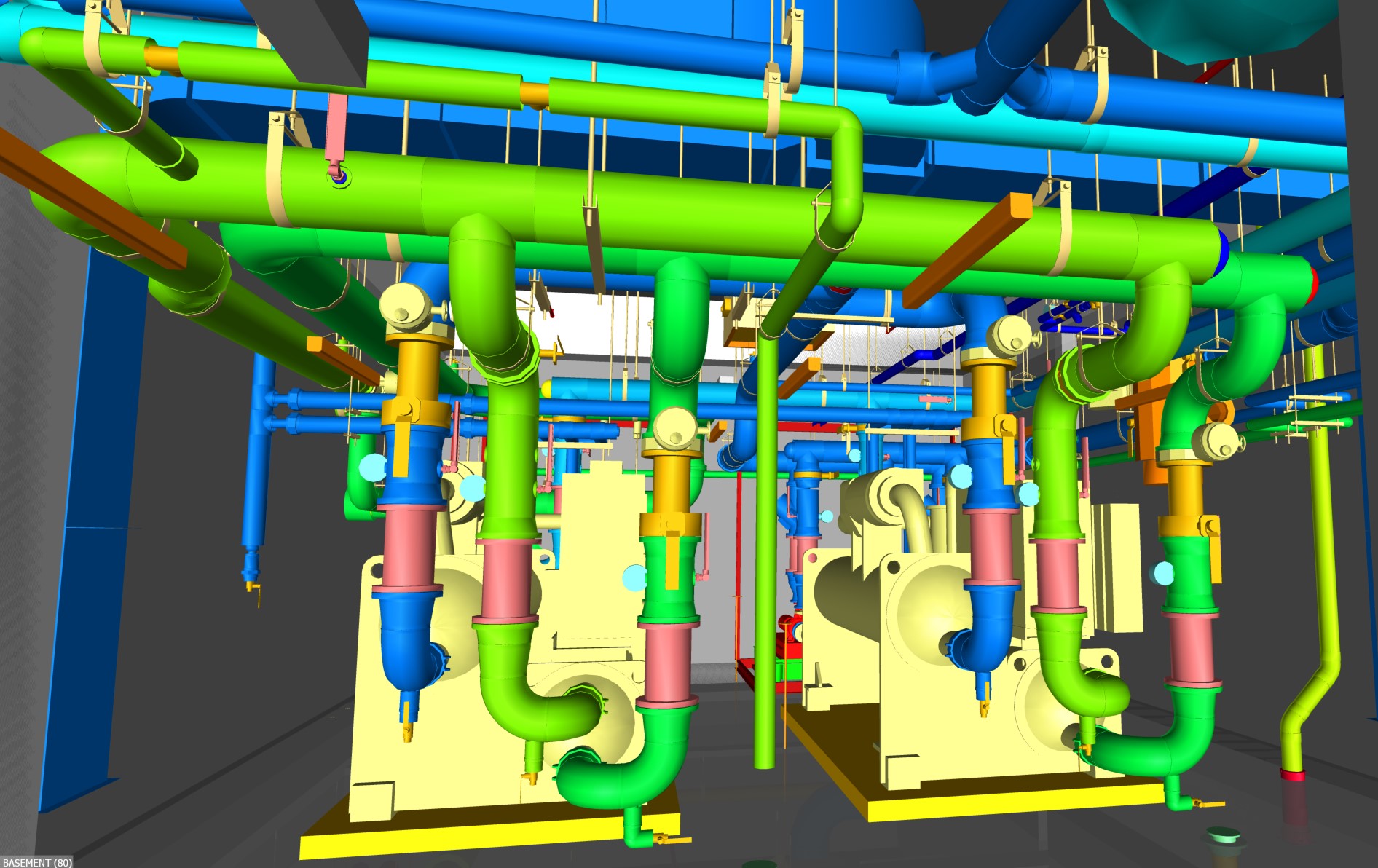

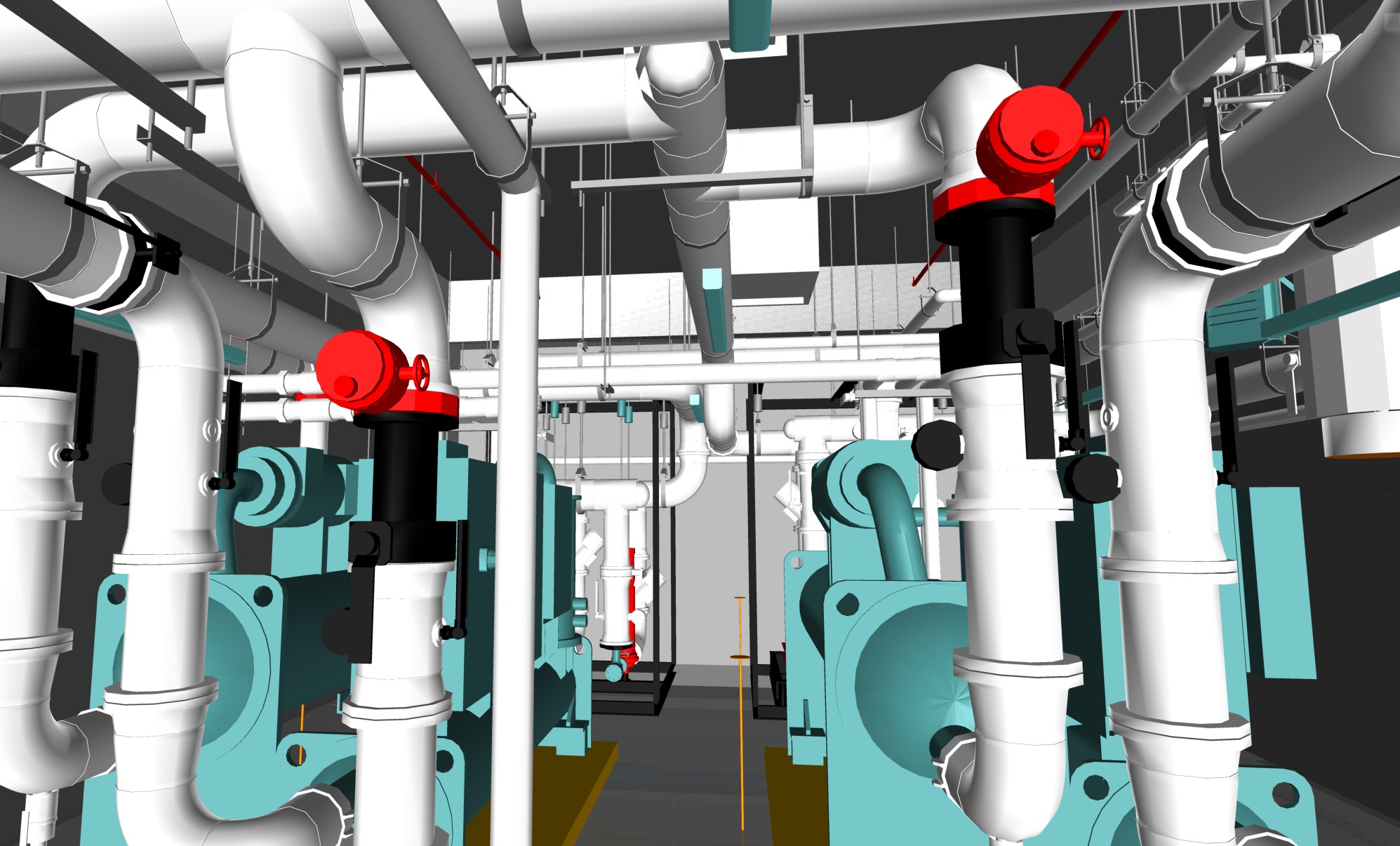

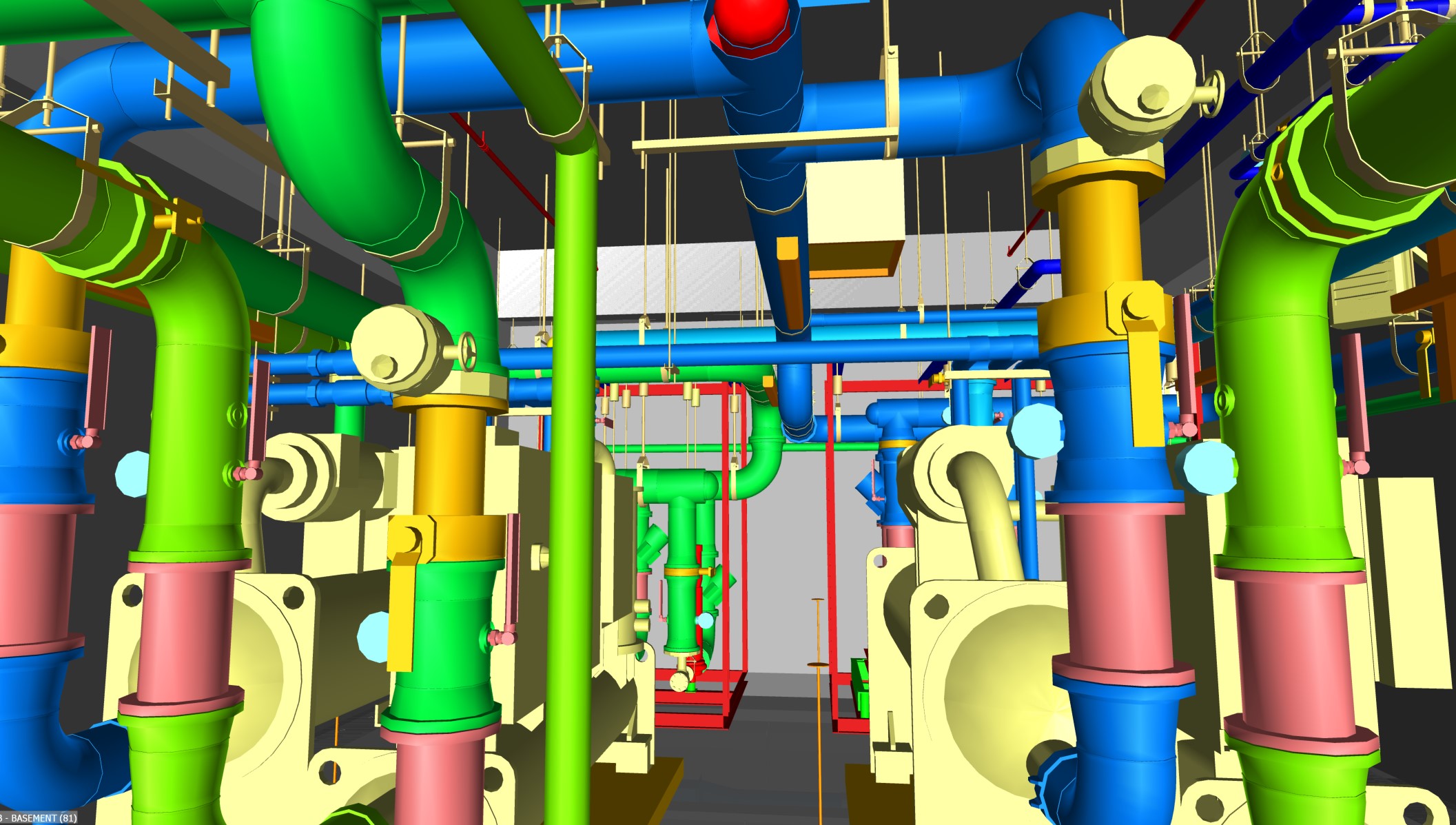

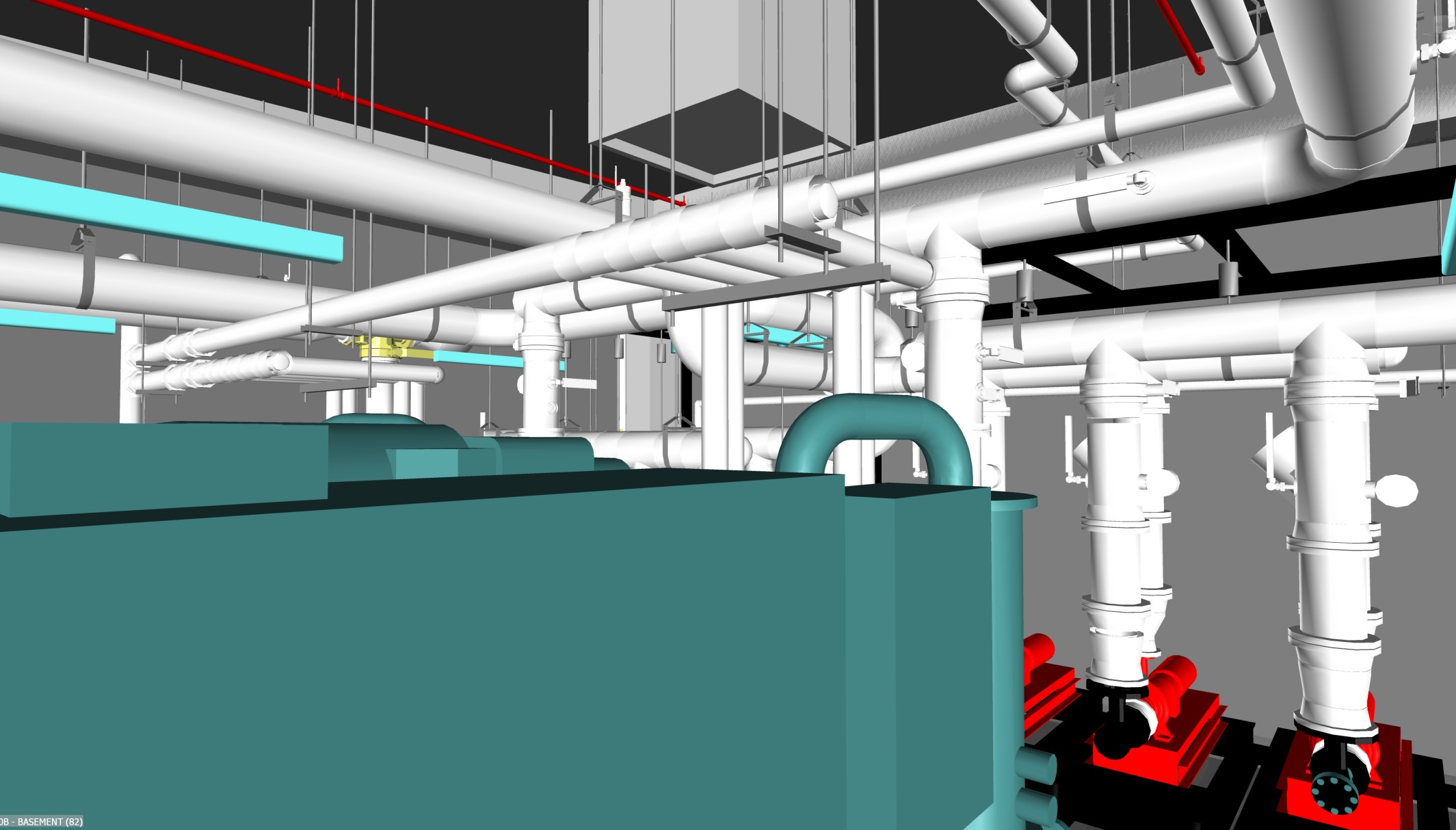

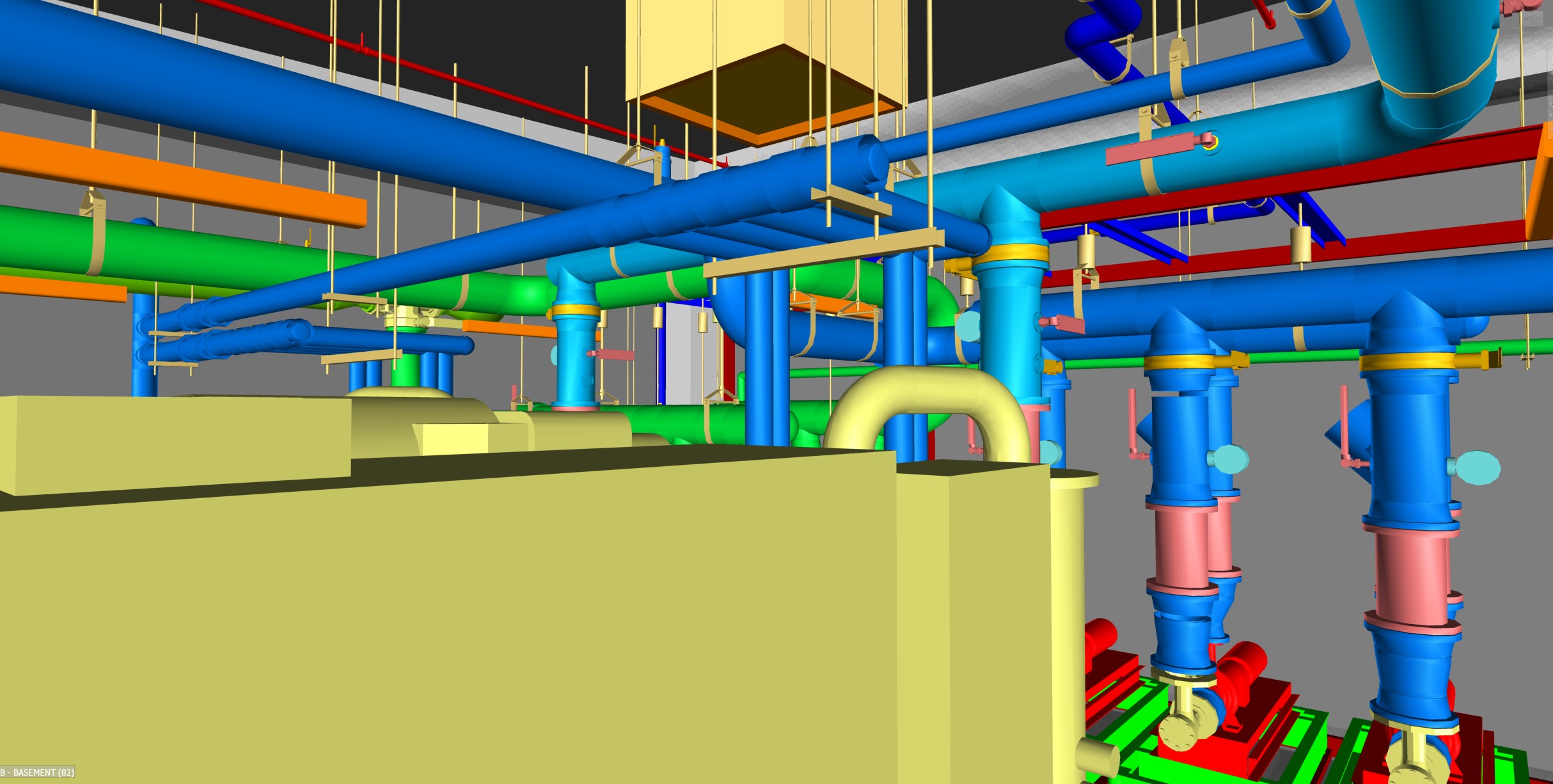

Mallick Mechanical installed chilled and condenser water pump skids, two hot water skids, to heating glycol skids, four steam-to-water heat exchangers, two chillers, an air separator, an expansion tank, two air handling cooling towers – including two basins, two field mounted fan motor shrouds, two service platforms – and a steam-to-steam generator.

STRATEGIES

When planning for this project, Mallick Mechanical Contractors understood there would be a heightened emphasis on prefabrication due to the project specs received in mid-summer. To preserve vital project time, Mallick Mechanical designed and installed four separate pump skids.

The chilled water consisted of three 10-HP pumps, the condenser water consisted of three 15-HP pumps and the three-heating water glycol, and the three hot water pumps were each made up of 7 ½-HP pumps.

Each pump skid consisted of 324 cubic-ft. of preassembled steel, allowing the prefabricated piping, hydronic specialties, and the inertia bases to be tied in place when installed.

The condenser water pump skid was especially unique since these three pumps were all in-line units, per the engineer’s design, and it was recommended from the manufacturer that the best method of installation was for them to be free-hanging and supported entirely from their respective header piping.

This was challenging due to the pumps floating inside of the prefabricated cage, which had to be rigged to the penthouse and skated into place while carefully controlling the excessive swinging and motion within the cage.

From receiving the initial pump product data in mid-June, the Mallick team was able to get the pump submittals approved, order the appropriate material, complete the needed fabrication, rig and set the pump skids by September – a feat that required a lot of internal and external coordination and allowed the project’s concrete schedule to be completed.

The project’s initial schedule entailed 9 separate riggings, but Mallick Mechanical’s solution-oriented approach decreased the necessary riggings to 4.

CHALLENGES

Due to coordination conflicts discovered by Mallick Mechanical and other trade partners early into the planning process, it was agreed the penthouse would have to be redesigned.

Over the course of the following month, Mallick Mechanical’s project management and VDC teams met with Clark Construction and the design team three times a week to create a more efficient and improved penthouse to better serve the building’s occupants.

These meetings to discuss coordination between all parties were crucial to obtaining the University of Maryland’s desired system and meeting ownership’s expectations.

The redesigned 5,800-sq. mechanical room – which spread across two levels – includes 5 mechanical and 9 plumbing systems. Mallick Mechanical’s project coordination team and leadership played a significant role in penthouse coordination. Mallick Mechanical dedicated many hours to collaborating with EYP Architecture & Engineering in an effort to enhance the previous design and create a solution that exceeded expectations.

These frequent meetings also allowed Mallick Mechanical’s team to detect future complications ahead of time and provide solutions to EYP and Clark Construction.

Through the entire project, Mallick Mechanical’s largest challenge came when the project team was informed of a new required flushing procedure for the steam system, involving an air flush and a full pressure steam flush with no use of water.

The flushing procedure was vital towards confirming the design and all related piping were assembled correctly and operate efficiently while also verifying it would properly connect to the University of Maryland’s central steam plant.

When Mallick Mechanical’s Idea Factory team was notified of this, all appropriate parties met to discuss an appropriate approach to conquer this challenge while remaining on schedule and meeting other important project deadlines.

After confirming a plan of action from our superintendent, project manager, foremen and VDC department, Mallick Mechanical dedicated two months of necessary preparation – which included extended weekday and weekend shifts — for the flushing procedure by installing 300-400 feet of temporary piping.

The temporary piping allowed Mallick Mechanical to bypass all 10 pieces of equipment, steam traps, meters and PRV’s for the flushing procedure and ensured of no damage to such equipment.

The flushes were split into 5 separate air and 5 separate steam flushes to ensure the system was effectively flushed section by section. Also steam, steam condensate and clean steam all had to be flushed separately, leading the Mallick team to be precise through each step of the flushing procedure.

Though faced with a difficult and complex situation, Mallick Mechanical’s Idea Factory team overcame this flushing procedure with no major setbacks that impacted the progress of the project nor other trade members.

TESTIMONIAL

“I thoroughly enjoyed working with Mallick Mechanical on a complex laboratory project for a higher education client in the Mid-Atlantic region. From the start of the project, Mallick’s attention to the submittal process and material procurement was a differentiator. By becoming an integrated member of the team, it was clear that every person from leadership to the crews were committed to the success of the project.”

– Ryan Knox, Project Executive, Clark Construction